|

Nose or Base Strike: Analysis of Bullet Orientation in a Ricochet During a recent homicide trial in San Diego, testimony was given concerning the ballistics of the fatal .22 bullet. There was evidence of a second strike on a portion of bullet's mushroomed surface (Fig. 1A). It was alleged that the missile was tumbling when it struck the second object and that this second strike was from the direction of the base toward the nose of the bullet. In this case, the direction of the bullet impact on the second surface had important implications for the crime scene reconstruction. As can be seen in Fig. 1A, the direction of the second impact is at about a 45 o angle from the central axis of the bullet and there is a peculiar direction change of the tool marks in a portion of the strike zone. A careful examination of the bullet's second impact surface suggests that the direction of this strike was toward the base of the bullet (i.e., from left to right in Fig. 1A).

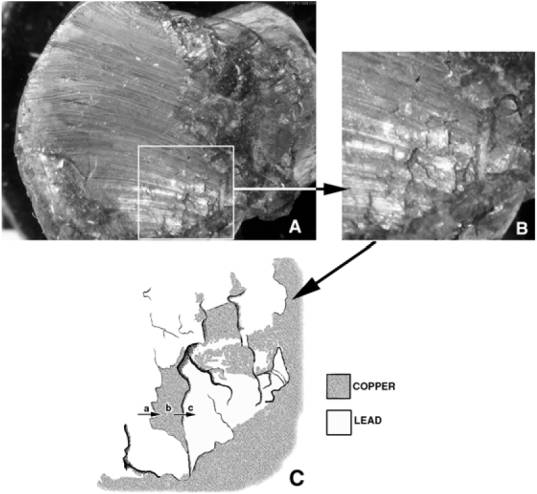

Figure 1. The questioned .22 bullet. A: The second impact area showing the region (box) of apparent lamina. B: An enlargement of the box area in A. C: Drawing of the region showing the distribution of copper (uniform stipple) from the .22 bullet coating. This case was reported previously (1). In that paper, evidence was provided which supported a scenario that the copper-coated .22 bullet went through window glass prior to hitting the victim. Both the mushrooming of the bullet as well as the second impact surface (Fig. 1A) were likely the result of the bullet's interaction with window glass (1). Regardless of the identity of the second impact surface, a distinctive feature associated with the bullet's second impact defect attests to the orientation of the bullet when it struck that second surface. Figure 1B is an enlargement of a portion of the second strike area shown on the victim's bullet in Fig. 1A. In this region of the victim's bullet are a series of apparent overlapping laminae. The surface of each lamina has tool-like marks and in this sequence of the laminal surfaces are remnants of the copper coating from the .22 bullet surface. Figure 1C is a drawing of this area which maps the distribution of copper (uniform stippled areas). In one part of this area, the overlapping lamina-like surfaces are particularly well defined. Copper alternates with lead on the laminal surfaces. Arrows in Fig. 1C indicate the direction of the overlap. The surface of layer "a," overlaps surface "b." The surface area of "b" is copper coated. Surface "b" overlaps surface "c." The laminal surfaces marked "a" and "c" do not have copper associated.

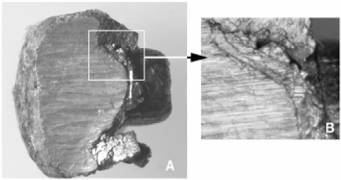

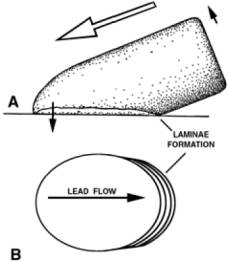

Figure 2. Test bullet that was hit at approximately a 30 o angle on a concrete surface. A: The .22 bullet showing a region of laminal formation (box). B: An enlargement of the boxed area on Fig. 2A showing the distinctive laminae on the trailing edge of the strike zone. A number of .22 bullets that were mushroomed by being fired through window glass (and caught in a cotton box) were clamped on their bases in a Visegrip TM pliers and struck, nose leading, at approximately 30 o angle on smooth concrete surface. The result of one of these simulated bullet strikes is shown in Fig. 2. The bullet (Fig. 2A) showed laminal structures on the trailing edge of the impact zone on the bullet (Fig. 2B). The front margin of the strike area (Fig. 2A) is uniform with no laminae. The formation of trailing-edge laminae on the bullet is likely associated with a lead bullet ricochet. As shown by diagram (Fig. 3A), the bullet hit the object at an angle. The forward force of the bullet impact tends to push the bullet's nose into the object's surface with the base of the bullet rotating away from that object. The lead in contact with the strike surface flows toward the base of the bullet as it engages that surface. Small wavelets of lead that are apparently created during this process flow in the opposite direction of the bullet travel while the bullet engages the surface. As the bullet base rotates on this surface more wavelets are created. Thus, the trailing edge of the bullet impact area is left with the impression of laminae as shown in Fig. 2B.

Figure 3. A: Diagram of a lead bullet in the process of a ricochet strike on a surface. White arrow: the direction of the strike. Black arrows: direction of rotation of the bullet. B: Diagram of the bullet's contact surface showing the probable lead flow during contact with a surface. The presence of laminal features on the margin of the strike zone of a bullet is an indicator the direction of that strike. When the second impact zone was created, the .22 bullet in question likely struck near its nose. Reference 1. Burnett, B.R. 2000. A shot through the window. J Forensic Sci 2001;46(2)379-385. Reprinted from: International Association for MicroAnalysis 4(2):14-15 © BRYAN BURNETT Bryan Burnett |